Mechanical and Bioengineering Labs

College of Engineering

Hands-On Skill Building

The Energy Systems Suite is home to the Fluid Dynamics Laboratory, the Mechanical Measurements Laboratory, the Engine Test Cell, and the Small Engines Laboratory. This facility provides the opportunity to study the laws governing work, heat, and energy conversion and to explore the use of standard measurement equipment, calibration techniques, and computer data acquisition.

Fluid Dynamics Laboratory: students explore fundamental fluid dynamics concepts using the wind tunnel and the supersonic nozzle.

Mechanical Measurements Laboratory: students learn the science of experimental methods by working with state-of-the-art measurement equipment, calibration techniques, and computer data acquisition.

Engine Test Cell: students explore and analyze the performance of a Caterpillar diesel engine.

Small Engines Laboratory: students operate a Cooperative Fuel Research engine and a natural gas turbine to study their performance and compare to theory discussed in their thermodynamics coursework.

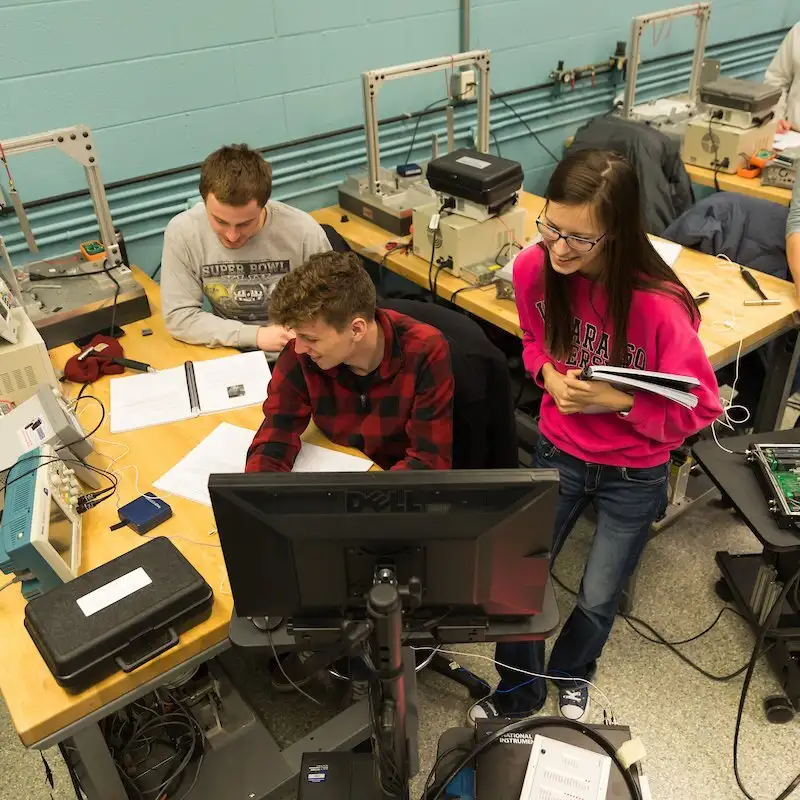

- Mechanical Measurements Laboratory

- Oscilloscopes

- National Instruments Data Acquisition and Signal Processing Hardware

- LabVIEW Software

- Function Generators

- Heat Power Laboratory

- Axial Flow Fan

- Wind Tunnel

- Diesel Engine

- Gasoline Engine

- Gas Turbine

- Supersonic Nozzle

- Solar Collector

- Heat Pump

- Wind Turbine

- Thermodynamics II

- Cooperative Fuel Research Engine

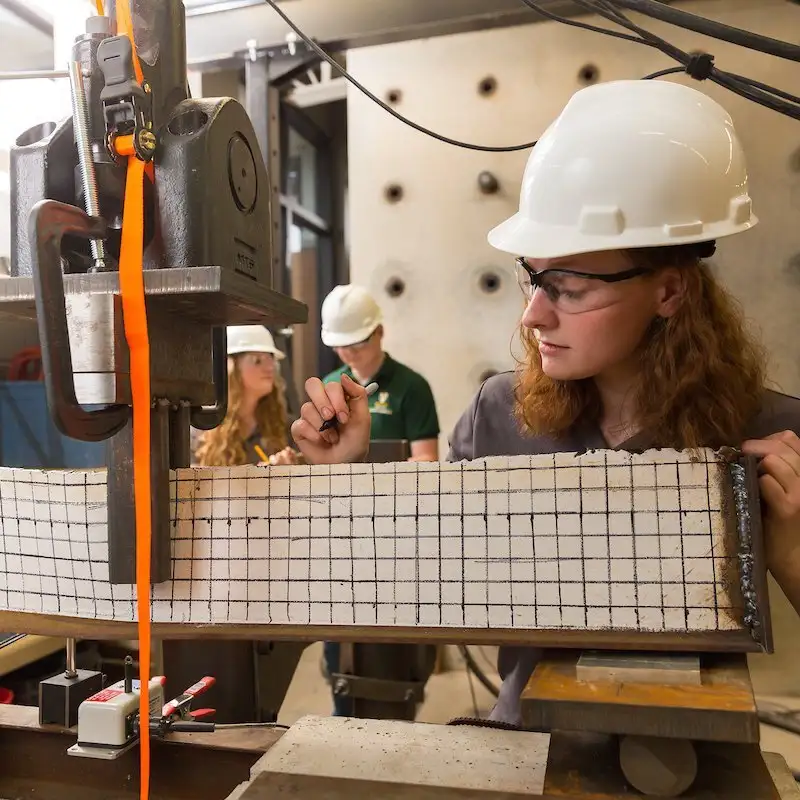

The materials science and engineering laboratory provides students with hands-on experience in materials science and engineering:

- MTS Tensile Tester

- MTS Fatique Tester

- Microscopes

- High Temperature Ovens

- Mechanical Rolling Station

- Cut-off Saw

The mechatronics, vibrations, and controls laboratory provides students with hands-on experience in four areas of mechanical engineering:

- In mechatronics, students learn the fundamentals of automation such as digital logic, microcontrollers, programmable logic controllers, robotics, sensors, and pneumatics.

- In vibrations, students learn how structures react to a variety of input forces.

- In controls, students learn how to guide or regulate the operation of machines or processes.

- In analog circuits, students learn how to design and implement electrical circuits.

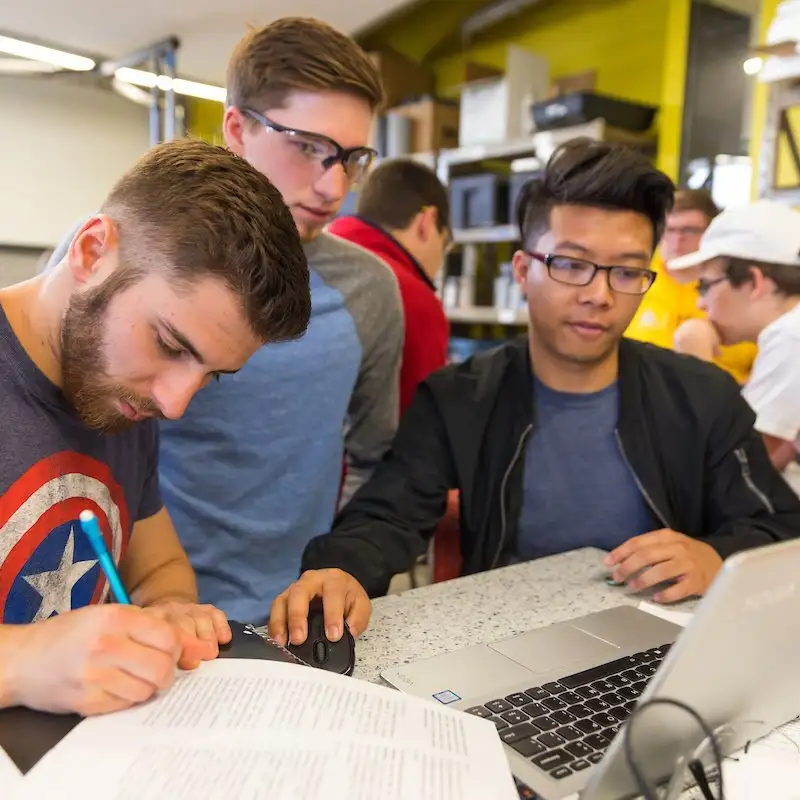

The Senior Design Laboratory in the new Fites Engineering Innovation center is shared by mechanical, civil, and electrical and computer engineering students. Teams of civil engineering students are assigned to work areas that mimic the actual workplace environment that they will encounter upon graduation. Within these areas, the students collaborate on a two semester project to complete a civil engineering project. Examples of projects include highway interchanges, building structures, water removal systems, etc. As an added bonus, senior engineering students have their own workspace for study groups, computer use, etc.

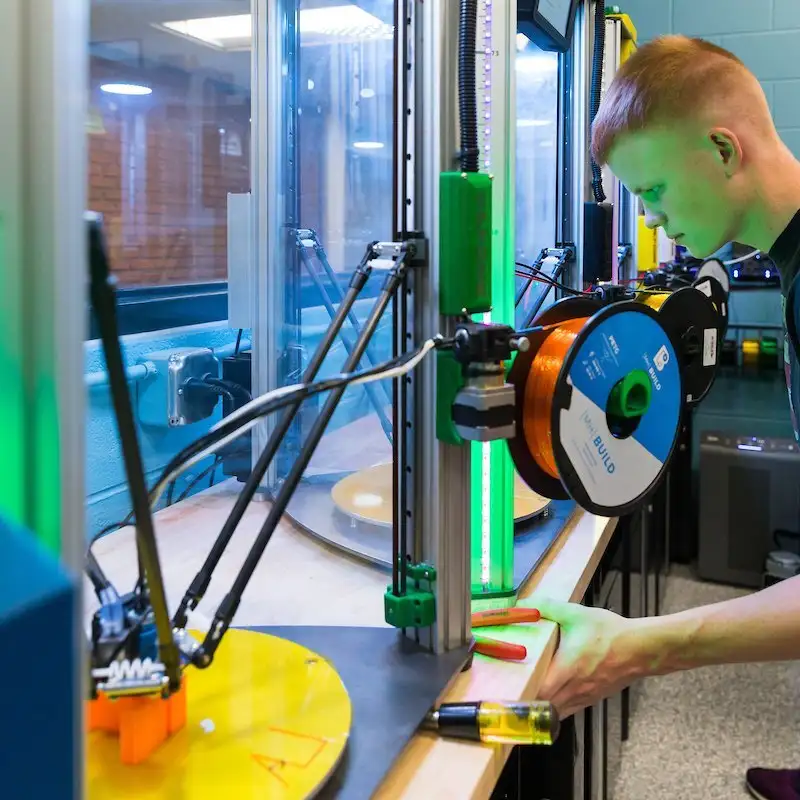

The James S. Markiewicz Manufacturing and Project Center includes the following laboratories:

- Manufacturing Processes Laboratory

- CNC Machining Laboratory

- Welding Laboratory

- Projects Laboratory

The laboratory is staffed by a full-time technician. After students are trained on the equipment, they may use the laboratory for student organization projects and Senior Design projects.

Projects Laboratory

During the fall semester, the projects laboratory is used by freshmen engineering students as part of the GE 100 course. During the spring semester, the projects laboratory is used by senior mechanical and electrical engineering students to assemble and test their senior design projects.

Equipment

- Haas TM-1 Vertical CNC Machining Center

- Haas VF-1 Vertical CNC Machining Center

- Haas TL-1 CNC Lathe

- Spetrum Rapid Prototyping Machine

- MIG Welder

- TIG Welder

- Manual Mills

- Manual Lathes

- Drill Presses

- Cut-off Saw

- Shears

- Presses

- Punches